1. Raw Edge

Process Features:

Direct cutting: After the towel is woven, it is cut directly with a cutter or laser cutter, and the edges are not sewn.

No lock stitch: The edge is the original fiber section and is easy to fall apart.

Common in: low-cost towels, industrial wipes or disposable products.

Advantages:

✔ The process is the simplest and the production cost is the lowest

✔ The towel is lighter and thinner as a whole, and has a large water absorption area

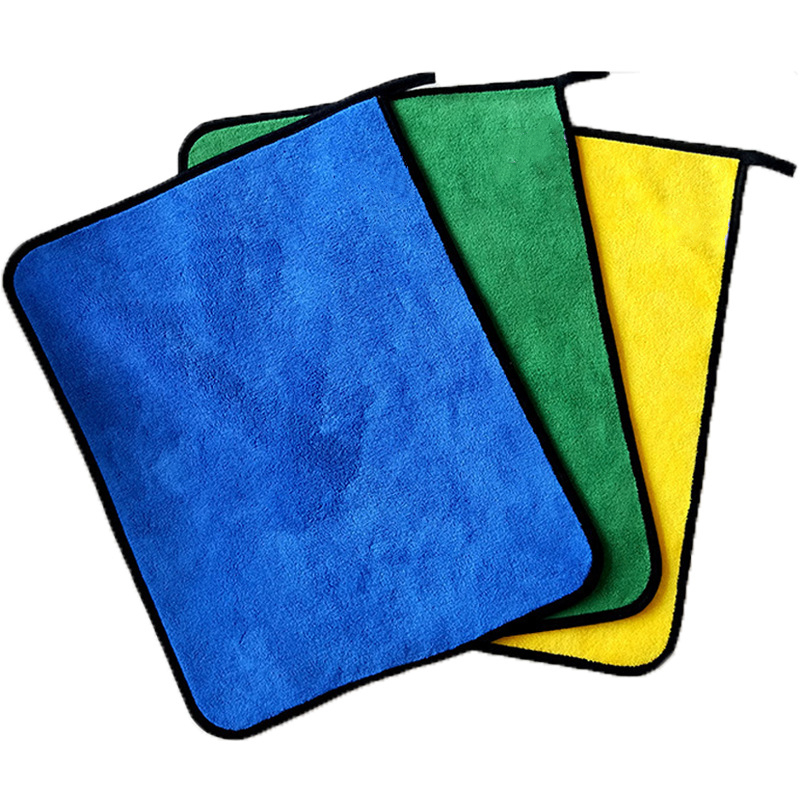

2. Overlock Edge / Serged Edge

Process Features:

Use an overlock machine (Overlock Machine): Use multiple threads (usually 3-5 threads) to wrap and sew the edge of the towel to form a serrated or wavy stitch.

The stitch wraps the edge: prevents the fiber from falling off, but does not add extra fabric.

Common in: mid-range car towels, household wipes, etc.

Advantages:

✔ More durable than trimming, prevents unraveling

✔ Moderate cost, high cost-effectiveness

✔ Softer edges, less likely to scratch car paint

3. Bound Edge

Technology features:

Extra Bound Edge Strips: Wrap the edge of the towel with twill strips or similar fabrics, and then fix it with a flat sewing machine or interlock sewing machine.

Double reinforcement: The edge is completely covered, and the stitching is hidden inside, making the appearance neater.

Commonly used in: high-end car care towels, gift towels, etc.

Advantages:

✔ Most durable, tear-resistant, suitable for long-term use

✔ Smooth edges to reduce the risk of friction when wiping

✔ Customizable colors or brand LOGO to enhance grade

Post time: Apr-23-2025